We’ve had clients who would be excellent candidates for storing their goods in our Kardex vertical storage systems, except for the fact that they have low ceilings. In these cases, they would need many short storage units, which makes it hard to justify. Some of those clients have decided that vertical storage and the benefits that come along with it are still worth pursuing, and bump-outs make sense.

What’s a bump-out?

A bump-out could be imagined as a tiny expansion, where a small concrete pad is poured along a section of the building’s exterior, and a rectangular silo is built on it to the desired height. It could be tall enough for a 30’, 40’, 50’ or taller storage unit. The silo would be big enough to have one or more storage units inside. The picking and replenishing window would be cut into what used to be the building’s exterior wall. The associate using the storage system would do so from inside the building where the low ceiling still exists.

storage unit. The silo would be big enough to have one or more storage units inside. The picking and replenishing window would be cut into what used to be the building’s exterior wall. The associate using the storage system would do so from inside the building where the low ceiling still exists.

There is an alternative

It’s important to note here that an alternative to the bump-out is the “top hat”. Instead of a tall rectangular silo being located on a new pad along the outer edge of the building, it can stick up through a part of the roof where it makes the most sense within the building. Add some bracing, raise a section of the roof, add some sides, and you are ready for vertical storage.

Bump-outs (and top-hats) might sound like a lot of work, and they won’t be inexpensive. However, compared to other options like a full-size expansion, relocating to a larger site, or offsite storage, this can be a strong contender with minimal disruption.

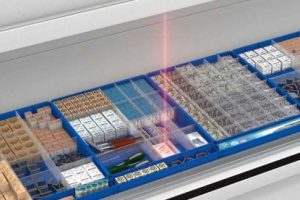

These vertical storage systems can help to buy back a lot of valuable floor space (up to 85%). If there is a plan to use that reclaimed space for revenue-producing purposes, the return on investment (ROI) can be prompt. When automated vertical storage is introduced, several benefits come with it. Not only the impact on space reclamation but also the inventory picking and

there is a plan to use that reclaimed space for revenue-producing purposes, the return on investment (ROI) can be prompt. When automated vertical storage is introduced, several benefits come with it. Not only the impact on space reclamation but also the inventory picking and  replenishing process can be done with less labor and better ergonomics due to a “goods-to-person” system. Speed and accuracy are improved with “pick-to-light” features. When interfacing with the ERP system, material transactions can be confirmed and immediately reconciled with the accounting department. This also contributes to the ROI.

replenishing process can be done with less labor and better ergonomics due to a “goods-to-person” system. Speed and accuracy are improved with “pick-to-light” features. When interfacing with the ERP system, material transactions can be confirmed and immediately reconciled with the accounting department. This also contributes to the ROI.

Think ahead

We tell our clients to build their bump-outs big enough for an additional storage unit in the future. This makes it easier when the need arises for more storage and the pad and structure are already done.

Some clients that have built a bump-out have adorned the finished exterior of the silo with their company logo. It’s a great look.

If you are considering how a vertical storage bump-out might be able to positively impact your company, call us. The sales and engineering teams at Abel Womack can work with you to configure a solution for your application. They will also help you calculate the ROI. Maybe bump-outs makes sense for you.

Leave a Reply

You must be logged in to post a comment.