Understanding the maximum capacity of your forklift is crucial, and it’s not a static number—it can change based on equipment specifications and usage. To ensure safety and prevent potential hazards, let’s explore how capacity ratings are calculated and what considerations are vital for maximizing safety.

Rules and Regulations

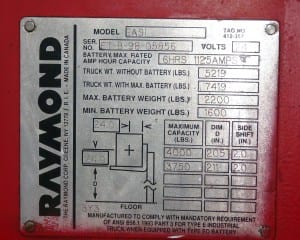

OSHA regulations mandate that all powered industrial lift trucks must have a clearly legible data plate displaying the truck’s maximum capacity. Additionally, any modifications or attachments affecting capacity, load center, or other critical statistics must also be documented on a plate.

plate displaying the truck’s maximum capacity. Additionally, any modifications or attachments affecting capacity, load center, or other critical statistics must also be documented on a plate.

These regulations exist for a reason: operators must always be aware of the equipment’s capacity for their safety and the safety of those around them. Operating a forklift beyond its specified limitations can lead to product loss, property damage, and serious injuries or fatalities.

A forklift’s load capacity is determined by the maximum weight it can safely carry at a specified load center and maximum load height. While this may seem straightforward, numerous variables influence capacity.

5 Key Factors in Forklift Load Ratings:

- Load Center

- The load center, stated on the data plate, represents the center of gravity of a load as positioned on the forks.

- For instance, a 24″ load center means the forklift is designed for a 48” X 48”load with a center of gravity 24″ high and 24″ from the face of the forks.

- Operators need to be vigilant about non-uniform load centers, as loads can vary in shape and size, impacting the effective capacity.

- Truck Center of Gravity

- Different forklift styles have varying weights and wheelbases based on use type and power source (battery vs. fuel).

- Operator training is crucial, as different forklift types have different limitations due to their center of gravity variations.

- Range of Motion:

- Lift, tilt, reach, side-shift, and other load adjustment capabilities impact load ratings.

- Adjusting a load changes its center of gravity, affecting the forklift’s load capacity.

- Factory-equipped load adjustments consider a worst-case scenario based on the intended range of motion.

Attachments:

Attachments:- Aftermarket attachments like carton clamps, push-pulls, fork extensions, and weigh scales can influence load ratings.

- Attachments can alter load center and add dead weight, impacting the forklift’s capacity.

- OSHA and ANSI require data plates and manufacturer approval for attachments affecting capacity.

- Battery Weight:

- For electric forklifts, battery weight is a crucial factor in capacity ratings.

- Always use batteries approved by the forklift manufacturer and avoid lighter-weight batteries.

Capacity Ratings Help Maintain Forklift Efficiency

For concerns regarding forklift attachments or part replacements and their impact on capacity ratings, consult with an Abel Womack expert for assistance. Remember, prioritizing safety is key to efficient forklift operations.

Leave a Reply

You must be logged in to post a comment.