Project Key Features:

|

Teradyne is a leading supplier of Automatic Test Equipment. The company delivers competitive advantages to the world’s leading semiconductor, electronics, automotive and network systems companies. In 2004, Teradyne had sales of $1.8 billion, and currently employs about 4,100 people worldwide.

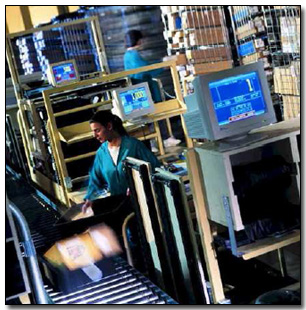

Being a leader in their industry meant streamlining their warehouse distribution system. Before the renovation, Teradyne had a standard stockroom operation including shelving units, bins and 7,000 parts arranged in part number sequence. Within 2 weeks after installing Abel Womack’s warehouse control system, the company more than doubled its productivity, going from 250 lines per person to an average of 600 lines per person.

Before the new warehouse control system was installed, their kitting accuracy was approximately 90%. After the installation of a bar code system, the accuracy as improved dramatically. By minimizing human intervention, the new system decreased errors and prevented the need for hiring more employees. Not only did the system become paperless, but the accuracy of item upon pick was virtually 100%.

The use of batching allowed Teradyne to substantially increase their lines picked per person, per hour. The average productivity measure indicated a capacity of 75-100 lines picked per person, per hour.

“After determining the capabilities of the AWCS system and Abel, we have a very high degree of confidence in both their product and the service they provide.”

Leo Montgomery, Materials Manager

Teradyne, Inc.