Project Key Features:

|

The company delivers competitive advantages to the world’s leading semiconductor, electronics, automotive and network systems companies. In 2004, Teradyne had sales of $1.8 billion, and currently employs about 4,100 people worldwide.

Teradyne’s SMT (Surface Mount Technology) operation was a low volume, high mix manufacturing environment. The operation required frequent set- ups, and Teradyne needed a way to best maximize the time their SMT machine was in operation. Abel Womack designed a software system for the SMT operation that combined the use of barcoding and scanning to optimize efficiency.

Abel Womack’s software system improved Teradyne’s efficiencies by minimizing set-up time. Through the use of the sophisticated software system, Teradyne employees could simulate each job, prior to its set-up, allowing the SMT operators a forward view of shortages.

Abel Womack’s software system improved Teradyne’s efficiencies by minimizing set-up time. Through the use of the sophisticated software system, Teradyne employees could simulate each job, prior to its set-up, allowing the SMT operators a forward view of shortages.

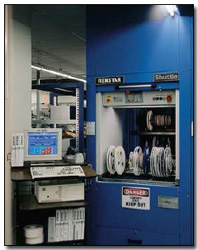

The system provided a complete knowledge of all inventory. This was accomplished by layering inventory. Bulk stock can be located in its bulk location, on a feeder, in a feeder bank, on the Remstar vertical carousels or on the SMT machine. This level of inventory control allowed Teradyne to virtually eliminate a shortage situation.

“During the setup of each job, the software will confirm the stock of each item being used. It continually tracks the quantity of each sub-component and allows for the “pre-plenishment of machine located SMT feeders. This is one of the keys to our efficiency and reduced downtime.”

Leo Montgomery, Materials Manager

Teradyne, Inc.