The lift trucks, rack, conveyor and warehouse management system in the new 40,000 SF warehouse addition in Walpole, MA enabled Siemens to “increase our daily order rates from 400 to 650 while decreasing our monthly pick errors from 25 to 6 per month“, said the Senior Supervisor in Plant Management at Siemens.

Abel Womack designed and implemented a plan to upgrade the entire distribution system for this major medical diagnostics company in Massachusetts.

The new addition had to meet 2 goals: support more SKU’s in a smaller footprint and automate much of the picking process. The goal was accomplished by implementing a system using 700 feet of new Hytrol and Automotion conveyor, a 4 level Unarco pick module, high bay Frazier storage rack and a RadioBeacon warehouse control/warehouse management system.

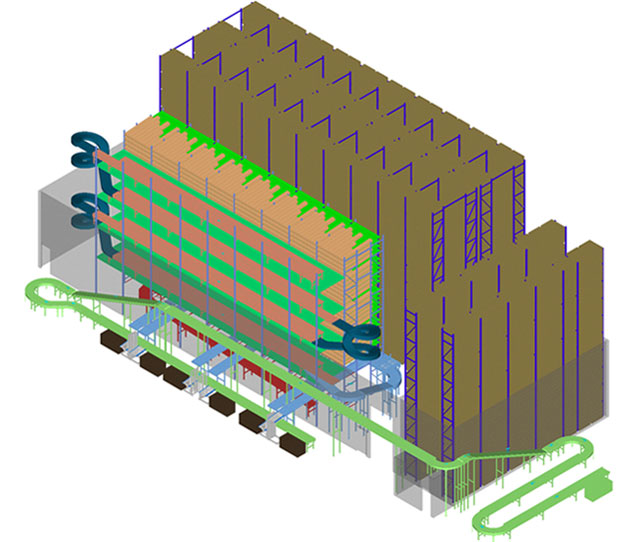

The diagram below shows the new layout with high bay rack, the pick module, pack stations, and shipping areas.

|