One of the most common business practices observed in the material handling industry is the practice of  choosing the most inexpensive equipment, often coupled with service support pricing. Doing so usually starts a bidding war from the chosen suppliers, causing the buyer to feel like they’re on common ground to getting the best deal possible.

choosing the most inexpensive equipment, often coupled with service support pricing. Doing so usually starts a bidding war from the chosen suppliers, causing the buyer to feel like they’re on common ground to getting the best deal possible.

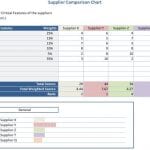

Relative value is many times determined through the quality of two or three vendor presentations in addition to the reputation of the equipment and the dealer. You may choose to go with the lowest price or just pursue this process to ensure best pricing, but make your decision on more than price.

Of course, initial cost is important, but there are a few uncommon areas not often taken into consideration that can drive up your true cost of ownership. Let’s look at a few.

Equipment Engineering: Good engineering designs incorporate quality as well as serviceability. Often, serviceability is overlooked when considering a purchase. The repair time on equipment with poor serviceability will drive your service labor repair costs sky high! The average technician labor rate is $125 per hour or higher. The mean time to repair and the frequency of repairs is much more of a cost driver than the labor rate. In fact, some who quote the lowest labor rates extend repair time to make them whole.

First Time Completion Rate: Often, response time is the focus of a repair. But what good is it if the service technician shows up right away and doesn’t have the parts or the ability to fix the equipment? Not good at all! The ability to fix the problem on the first visit and have the equipment back in operation is more important than how quickly a technician shows up just to tell you what the problem is, order the parts and return several days later for the repair. Excessive downtime costs you money!

First Time Completion Rate: Often, response time is the focus of a repair. But what good is it if the service technician shows up right away and doesn’t have the parts or the ability to fix the equipment? Not good at all! The ability to fix the problem on the first visit and have the equipment back in operation is more important than how quickly a technician shows up just to tell you what the problem is, order the parts and return several days later for the repair. Excessive downtime costs you money!

Parts Availability: Some equipment manufacturers’ parts come from overseas, creating a two to three-week lead time to get the part. Even parts made in America can take several days at times. Could you imagine having your equipment down for days, weeks or more? Make sure you deal with companies that have big parts inventories and their act together.

Parts Pricing: This is a big one! Sure, the equipment you’ve been quoted may be the most competitive, but when parts are needed, you then sometimes pay the price. Some parts can be double or triple what it should be- another way to make up for upfront lost profits if the quoted prices put the supplier under water.

Service Agreements: Pay close attention to the details of the agreement. Not all full maintenance agreements are created equal and the good ones have the service provider and the customer on the same side- both trying to minimize service costs. The bad ones may look attractive but ultimately pit the dealer’s interest at odds with those of the customer.

As you can see, there are several items to consider when purchasing a lift truck. Many customers go straight to the bottom line and only compare sell prices. However, are you really comparing the true value of equipment and an organization’s ability to service you? Share your comments below.

Leave a Reply

You must be logged in to post a comment.