As the COVID-19 pandemic has changed the way we do just about everything for the last several months, there are a few things that have been made crystal clear. One of those is the need for essential workers and businesses to operate at a high level, even during such unprecedented times. For produce and grocery distributors, keeping inventory fresh and available is not only a priority but a necessity as more people are eating at home than before.

Keeping produce fresh, stocking shelves quickly and efficiently, and having a well-designed warehouse are all crucial aspects  of their operation. Grocery distributors operate on slim margins and require quick turn around and superior equipment to stay on track. Labor can be very expensive, so having the best setup and equipment is a necessity to control cost and improve warehouse efficiency and productivity. Being able to juggle all of that is critical to running a successful business.

of their operation. Grocery distributors operate on slim margins and require quick turn around and superior equipment to stay on track. Labor can be very expensive, so having the best setup and equipment is a necessity to control cost and improve warehouse efficiency and productivity. Being able to juggle all of that is critical to running a successful business.

Here are some things you should know about creating and operating a smoothly run grocery distribution center.

Planning for Success

With any operation we always emphasize the importance of planning in every stage, and distribution centers are certainly no different. We can help plan new warehouses or even recommend modifications for an existing one. With your expertise about your business, we can plan for just about anything. The journey to success is one we like to take together, and we do what we can to get you there. The key is taking the time to understand where you want to be in 2-5 years, not just the next six months.

When talking with a business owner, nobody understands their business better than they do. Abel Womack is the expert in automated systems, intralogistics, stand alone products, custom design, and engineering. We need to work together to design a custom solution for the specific short-term needs and long-term goals, as there is no one size fits all approach.

Getting and Maintaining the Right Equipment

Fast turnaround, wash-down and abusive environments, cold storage, and corrosive fluids are a few reasons why it is imperative food distribution centers and warehouses use superior material handling equipment. At the end of the day, superior equipment is needed to have a well-running operation. The amount you spend upfront on high-quality equipment is much less than the extra money you would need to pay for more maintenance, lost efficiency, and operator downtime. Lower quality machinery will also take more time to complete the same tasks.

distribution centers and warehouses use superior material handling equipment. At the end of the day, superior equipment is needed to have a well-running operation. The amount you spend upfront on high-quality equipment is much less than the extra money you would need to pay for more maintenance, lost efficiency, and operator downtime. Lower quality machinery will also take more time to complete the same tasks.

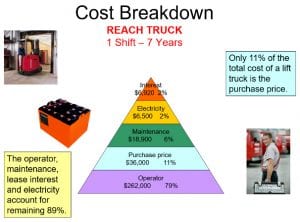

One of the hardest costs to quantify is downtime. Most managers and some executives just look at the cost of the repairs, but operator downtime is really the biggest cost driver. As you can see from the pyramid, the operator accounts for 79% of the cost of running a forklift over seven years. So, having an operator standing around or inefficiently redeployed while his forklift is being repaired costs a lot more than most owners and executives realize.

Essential Equipment at Grocery Distributors

Due to regulations and the need to keep grocery distribution centers cleaner, electric forklifts have replaced traditional propane trucks. One of the main reasons was to increase efficiency and reduce air quality problems caused by particulates from propane-driven truck engines. Three of the most common pieces of equipment seen and needed in grocery are counterbalanced trucks, reach trucks, and pallet jacks. Each have their own use which work better in different situations.

Counterbalanced trucks can be either sit down or stand up. These electric trucks  are best for handling 3,000-6,000 pounds of materials around a warehouse, dock, or trailer. You can add attachments like carton clamps to pick up large cartons easier, reducing the need for pallets and reducing the amount of wood shards in the warehouse. Forward bin dumpers handle large volumes of produce like grapes, citrus, and nuts making unloading and transportation much smoother. These are just a few examples of the many different types of attachments that can be used on counterbalanced forklifts.

are best for handling 3,000-6,000 pounds of materials around a warehouse, dock, or trailer. You can add attachments like carton clamps to pick up large cartons easier, reducing the need for pallets and reducing the amount of wood shards in the warehouse. Forward bin dumpers handle large volumes of produce like grapes, citrus, and nuts making unloading and transportation much smoother. These are just a few examples of the many different types of attachments that can be used on counterbalanced forklifts.

Reach trucks are widely used in grocery and food distribution for putting away and letting down pallets. They are ideally suited for narrow aisles as they are designed to operate tight spaces while reaching up to 40 feet or more in the air.

Pallet jacks and walkie riders are often used for loading and unloading pallets out of a truck and horizontal transportation throughout a warehouse. Pallet jacks and reach trucks often work in conjunction with each other. The reach trucks bring down reserves from upper levels to the first beam level or ground level when those locations have been depleted, and the pallet jacks are used for picking cases or pieces on those lower levels. This is becoming much more common with the proliferation of home delivery grocery services.

Making Your Equipment Last

From the different trucks you use to help load and unload product to the cold storage that keeps your produce and other  food fresh, ensuring the longevity of your equipment is important. Using safeguards such as IP65 rated wire connectors can help ensure your equipment in wash down, and cold storage areas where condensation can occur, will not short circuit and derail your work. Additionally, in corrosive environments where brine or salt is used, making sure your metal equipment is galvanized to protect against rust- a major health concern when dealing with fresh foods.

food fresh, ensuring the longevity of your equipment is important. Using safeguards such as IP65 rated wire connectors can help ensure your equipment in wash down, and cold storage areas where condensation can occur, will not short circuit and derail your work. Additionally, in corrosive environments where brine or salt is used, making sure your metal equipment is galvanized to protect against rust- a major health concern when dealing with fresh foods.

The Abel Womack team has extensive experience in all aspects of material handling, and we have experts with years of experience within the food distribution sector. We work with you every step of the way to make sure you are set up for success from the back room to the produce shelves. Contact Abel Womack today and see what a difference the right planning, materials, and equipment can make in your food distribution operation.

You also may be interested in our blog: Cold Storage Space is Really Heating Up

Leave a Reply

You must be logged in to post a comment.