Have you noticed new apartment buildings keep getting taller? Mainly because you can get  more value per vertical cubic space out of higher buildings. The same principle applies to warehousing when it comes to cost per pallet position and optimum cube utilization. More vertical pallet positions equate to a lower cost per position, providing you with more storage capacity per square foot and bigger profits.

more value per vertical cubic space out of higher buildings. The same principle applies to warehousing when it comes to cost per pallet position and optimum cube utilization. More vertical pallet positions equate to a lower cost per position, providing you with more storage capacity per square foot and bigger profits.

Everything is rising

Your business location is often a key part of keeping and efficiently servicing your customers, particularly when everyone wants everything immediately. One solution to staying where you are while increasing your capacity is raising the roof of your facility. By allowing higher racking and greater storage in the same footprint, you can avoid things like moving expenses, additional property costs, potential loss of customers, higher transportation expenses and taxes and all the hassles with relocation or secondary storage. It’s easier and less costly than you may think!

Keeping up with today’s demands

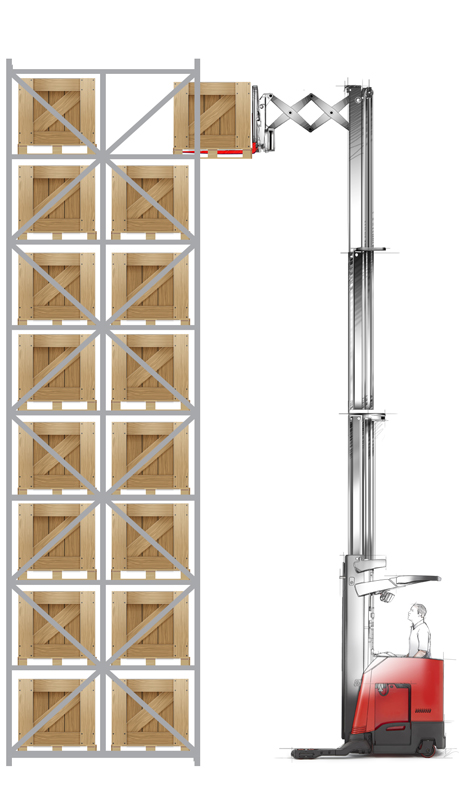

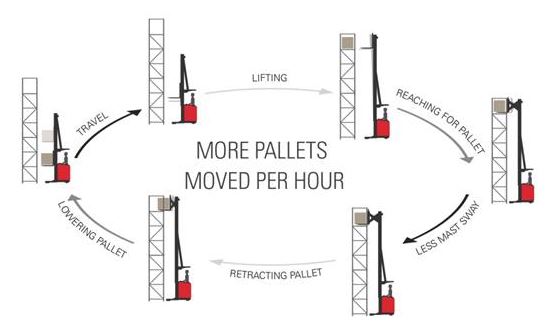

With loads getting taller and heavier, you need equipment that can rise to the occasion. The  new, more efficient Raymond Model 7530 and 7730 high capacity reach trucks have the highest lift heights in the industry at 542”( 8-10 levels high). With higher capacities at height and 15% greater energy efficiency, you get faster speeds but the same battery shift life for even greater productivity and profitability. This winning combination will help your operation keep up with demand and substantially reduce operational costs.

new, more efficient Raymond Model 7530 and 7730 high capacity reach trucks have the highest lift heights in the industry at 542”( 8-10 levels high). With higher capacities at height and 15% greater energy efficiency, you get faster speeds but the same battery shift life for even greater productivity and profitability. This winning combination will help your operation keep up with demand and substantially reduce operational costs.

Reach for more uptime, lower energy costs

To further improve productivity, the optional fork laser and/or camera can provide superior operator visibility while removing and retrieving pallets at such high positions. If you’re working in a cold storage facility, you know your operation is the most expensive type of storage facility, so maximizing pallet positions is critical. When it comes to cost of ownership in extreme environments, The Raymond Corporation’s cold storage equipment is the smart-spend brand. Their fork trucks are engineered for reduced energy costs and less frequent maintenance translating to the lowest overall cost of ownership in the industry.

Abel Womack and Raymond have you covered!

Consult with your local Abel Womack material handling specialist for ways you can implement more efficient space utilization today. Our plans can include compact storage, slotting analysis, and choosing the right equipment to help increase your business’s capabilities and profits. Working with you, we can create cost-effective, customized material handling solutions for significant space savings, increased levels of productivity, and quick and substantial returns on investments for your warehouse.

Leave a Reply

You must be logged in to post a comment.